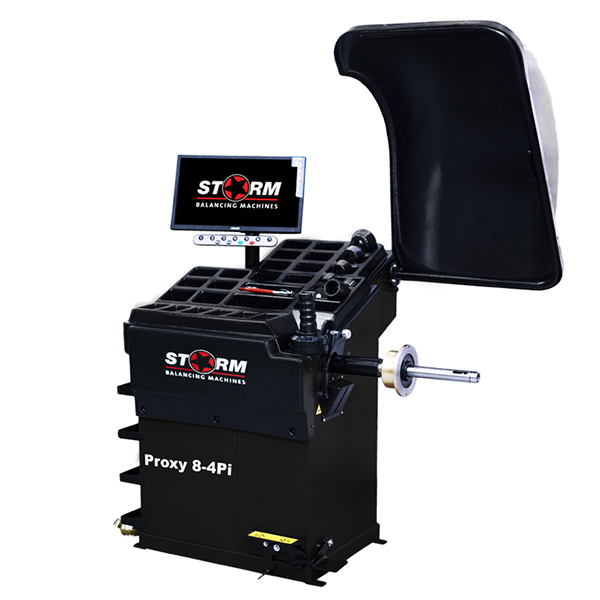

Description

Super-automatic Premium Class Vibration control machine and Wheel Balancer. Up to 180 balanced wheels/hour.

Fully automatic input of wheel parameters. The extended shaft for installation of a wide wheel. This wheel balancer is equipped with pneumatic wheel attachment and a laser point “dot”, electronic distribution of various data on the operation of the machine and the results of wheel diagnostics, as well as a wheel diagnostics function with indication of deformation sites. We improved the previous version of balancing machine Proxy 8-2p/pi increasing the stroke grip to 65mm.

Complete wheel measurement cycle for R14 – 5 seconds (acceleration, measurement, deceleration).

Complete wheel measurement cycle for R20 – 8 seconds (acceleration, measurement, deceleration).

Main functions:

- The “AUTO-SONAR” function provides the ability to read disk parameters in automatic mode using an ultrasonic sensor.

- The “AUTO PROGRAM” function allows the user to perform balancing in any automatic or semi-automatic mode without using buttons (the machine chooses the desired mode and intelligently adjusts its work to the working habits of the operators).

- The “3D-DISK” function allows you to see a three-dimensional projection of the wheel on the monitor.

- The option “BRAKES”, if necessary, allows to reduce the time of the balancing process, connecting not only the engine, but also the brake cheek. This should save an average of 6 seconds per cycle. This feature makes this model one of the “fastest” among world analogues in the premium segment.

- Laser pointer “point” in the “6 o’clock” mode: special red spectral laser dots indicate the operator’s position for setting weight in different planes. It clearly shows the position for cleaning, degreasing and adding self-adhesive weights.

- Automatic correction weight type detection (self-adhesive or articulated weight).

- Correction weights are installed through the distance entry unit.

- Special function for checking disc bounce with a graph of results visible on the monitor. This feature allows you to identify and visualize the disk area curves and show them to the client to explain that additional alignment or replacement of the disk is required.

- E-mail sending of various data on the operation of the machine and the results of the diagnosis of wheels.

- The “AUTO-SUPPLY” function automatically turns the wheel into a working position, so there is no need to manually turn the wheel.

- The “MEMORY” function allows you to save statistics on operations performed on the balancer, as a general summary for the selected period, and individually by each operator (up to 7 operators): the number of balanced wheels, the number of attempts, the number of clips or sticks used – on the scales).

- Motorcycle wheel balancing mode (motorcycle wheel adapter is additional option).

Technical features:

- Illumination of the inner surface of the wheels. This is achieved through the use of two high-performance light-emitting diodes located on the spindle side of the machine body.

- Fast work is guaranteed by an electromagnetic brake, which saves time on deacentation and balances more wheels.

- Skin-to-skin installation to wall.

- The refurbished modern input panel with an improved design is located exactly under the monitor, and the angle of inclination can be individually adjusted for each operator. User friendly menu, a choice of backgrounds, a durable tabletop with a multitude of sections, memory for 7 operators are functions that allow you to quickly balance the wheels with high quality and minimal time and labor consumption.

Main specifications:

| Accuracy readability, G | 1 |

| Wheels parameters: | |

| Rim diameter, inch | 9 – 28 |

| For manual input, inch | up to 30 |

| Rim width, inch | 1,5 – 20 |

| Maximum assembled wheel diameter, mm | 1370 |

| Max. wheel weight, kg | 75 |

| Power supply, V | 220±10%, 50 Hz |

| Max. power consumption, W | 350 |

| Pneumatic working pressure, kg/sm2 | 6-8 |

| Dimensions (mm): | |

| Balancer | 1500*880*1850 (h) |

| Package | 1300*930*1525 (h) |

| Machine weight, kg | no more than, 137 |